Newly emerging technologies are actively replacing old ones. They give humanity unlimited opportunities, increasing the likelihood of the high-quality performance of any complex work. One result of these technologies is liquid lenses (LL). They have unique characteristics, making them suitable for hundreds of types of work. Already, such products are popular in many fields of activity and deserve thousands of good reviews from experts.

How does liquid lens technology work?

Since ancient times, mankind has been using lenses. They allowed our ancestors to fight, make important discoveries in biology, astronomy, and medicine, and perform a vast amount of simple and complex work. Gradually, these products improved, and the scope of their application expanded. All this led to the emergence of LL. They have become available to people relatively recently but have already shown themselves well in business. They are ahead of ordinary lenses in many ways, so they quickly take the lead in the dispute about the most valuable products.

LLs are a complex modern development, but the principle of their work remains relatively easy to understand. It is based on physical and chemical processes that occur during the interaction of electricity and water.

Short description of LL action:

- The diligent work of LL begins with the formation of a microscopic drop on a water-repellent surface.

- Next, the drop is exposed to a current, which causes the water to press against the surface below it. The minimum electric charge is used at this stage, which is enough to complete the described task.

- The attraction of a drop inevitably changes the curvature of its outer surface. Due to this, the light passing through it is refracted at a different angle.

- Smoothly changing the strength of the applied charge, users get the required droplet surface bending, allowing them to achieve good focusing.

- The result is increased clarity and improved image quality.

Why use liquid lens technology?

The process of improving any technology has no limits. That is why scientists develop something new every day, trying to improve everything people actively use. The same thing happens with LL. They are actively improved, becoming as helpful as possible. Nowadays, their purpose is to get rid of the need to install 2-3 or more imaging systems. This approach makes it possible to significantly reduce the size of optical instruments, making them more convenient for storage, transportation, and operation. In addition, LL opens up new opportunities for humanity, allowing them to cope with many tasks.

An important reason why LL is implemented in optics is to speed up the work. Thanks to simplified operation and ease of adjustment of various parameters, it is possible to significantly reduce the time spent on focusing and some other processes. Also, everyone needs to know that LLs have a relatively low cost and equipping optical devices with them is affordable.

Mechanical lenses vs. liquid lenses

Since the advent of LL, disputes about their effectiveness have remained strong. Some experts claim that they will never be able to fully replace mechanical lenses, while others say that this process has already begun. To determine whose opinion is closer to the truth, you need to compare both types of lenses with each other. Initially, LLs were called changers of mechanical products. They are now actively installed in various optical devices, gradually expanding the scope. However, they have yet to succeed in completely replacing automatic lenses.

Legacy products remain popular due to their well-known benefits. The main one is the low cost, thanks to which everyone can buy mechanical lenses. Also among the advantages include versatility and low probability of breakdowns. All of these advantages are a weighty argument in favor of automatic lenses. However, they are crossed out by shortcomings that LL needs to have. Chief among them is the difficulty of adjusting the focus. Also, experts note the increased time spent on obtaining a high-quality image.

Modern LLs are devoid of the shortcomings of their predecessors. In addition, they have many positive qualities. These include ease of use, high speed, and access to smooth focus adjustment. All of the above tip the scale in favor of LL. At the same time, no one even thinks about the complete rejection of mechanical products.

Advantages of liquid lenses

LL is famous not only because of its status as an exciting novelty. They have dozens of positive features that make them superior to all their predecessors.

Main advantages:

- Simplicity. LL has a small number of design details. This makes them highly resistant to breakage and various external factors. It would be best if you also remembered that the simplicity of the design helps reduce the product's size and weight.

- Versatility. Modern LLs can be used anywhere. In all cases, they will perfectly cope with the tasks set, increasing the efficiency of the devices. Due to its versatility, LL is often used in medicine, pharmacology, industrial and scientific fields. In addition, they are actively exploited during the production of various equipment.

- Speed of work. New lenses can change focus in just a few moments. This advantage allows users to adapt the technique to current needs. In addition, speed is also observed when forming an image of the required quality.

- Freedom to choose focus settings. LLs help change the focal length in the maximum range. Their predecessors, previously considered the standard, need to be more capable of this. The increased focus adjustment range allows you to select the ideal value depending on current needs.

- Extended service life. LL retains its properties for several years. Because of this, they do not need to be changed often and spend much money on it. Also, a positive point that increases the life of the lenses is resistance to various external influences that can disable models of other types.

- Economical energy consumption. During operation, LL uses electricity. However, the magnitude of the generated charge is so microscopic that it is not even worth considering enormous energy costs. This circumstance does not affect the period of operation of optical equipment in autonomous mode, leaving it at the same level.

- Stabilization. LL has a unique ability to dampen any vibrations. This is very important when such products are installed in cameras. Here they simultaneously perform their direct duties and act as an image stabilizers. Thanks to this, even trembling hands or a gust of strong wind will not adversely affect the state of the photo.

- Silence. Mechanically, the details are absent in LL, so their work always remains elusive to the ear. This critical advantage will be needed in cases where you need to make optical equipment as quiet as possible in operation.

- Ease of care. You don't have to take care of liquid lenses at all. Even without this procedure, they will work great for a long time. This contrasts with ordinary mechanical lenses, which must be constantly wiped from moisture and dust accumulated on the surface.

- Environmental friendliness. LL is made from quality materials that are safe for nature. Such products are also safe for humans. They do not emit substances hazardous to health and do not create harmful radiation. Because of this, even their disposal process will become the most straightforward task.

Who is using liquid lenses now?

LL are not only fashionable new developments but also valuable products. Thanks to this, they are successfully implemented in dozens of areas of activity. They all show good results and make coping with many vital things possible.

Applications of LL:

- Medicine, pharmacology. Everything that is connected with the treatment of people needs optical devices in which LL can be installed. Most often, LL is installed in high-precision equipment used to examine patients. These products will turn outdated models into modern optics, increasing the accuracy and quality of their work. Also, modern lenses are useful during simple and complex operations. In pharmacology, LLs will also be manageable. Already, they help specialists develop new effective drugs for many dangerous diseases.

- Industry. Plants, factories, and other enterprises can only do with LL. These products replace obsolete lenses, making the equipment used more modern and in demand. Most often, LLs become one of the parts of various assembly lines. They are also placed on equipment designed to perform high-precision work.

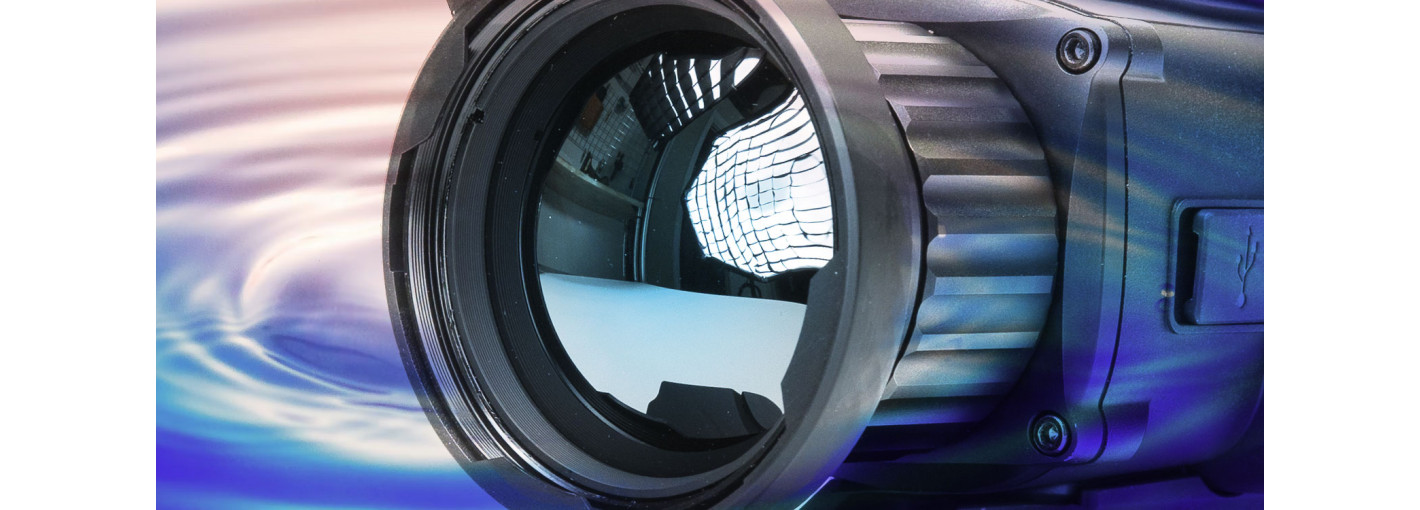

- Manufacturing technique. LL was also useful for manufacturers of various equipment that people use every day. In most cases, new lenses are introduced into the optical system of video cameras and cameras. Their presence makes it possible to select the focus settings as accurately as possible, simplifying the process of focusing on the subject being shot.

The appearance of liquid lenses has become a real breakthrough in the field of optical devices. These products have excellent performance characteristics, due to which they are used in most areas of activity. They made it possible for people to perform many types of work that were previously inaccessible with better quality. This technology will only develop in the future, opening up new opportunities for mankind.